Umshicileli we-Inkjet ngoku yi-ofisi yethu iyimfuneko engumncedi olungileyo, umshicileli ulula kakhulu ukusebenzisa, kodwa kumshicileli xa kukho ingxaki kufuneka sijongane nayo njani? Ishwankathela indlela encinci eqhelekileyo kumntu wonke namhlanje!!

【1】

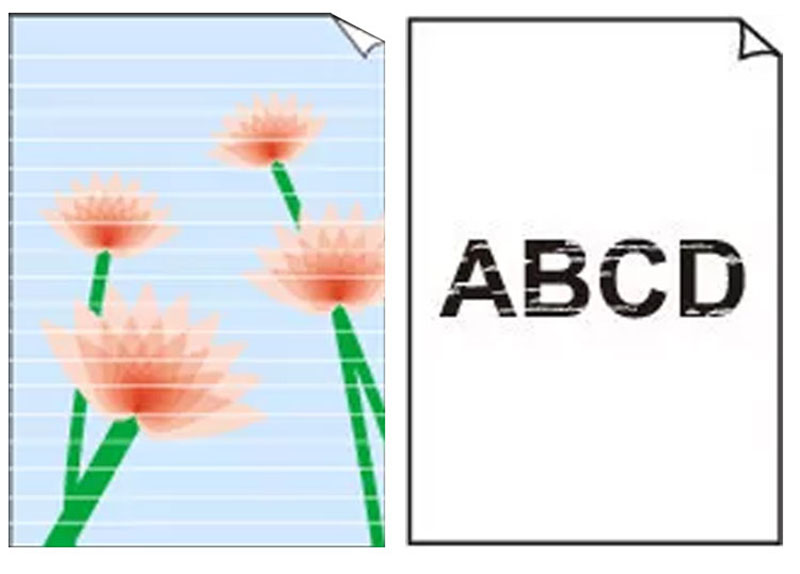

Shicilela ngemigca ethe tye (izithuba ezincinci), okanye ukufiphala

[Isizathu sokusilela] Imigca emincinci esecaleni, ebonisa ukuba eminye imilomo yentloko yoshicilelo ayiphumelelanga ukutshiza i-inki ngokuchanekileyo.

[Ukusombulula ingxaki] Nceda ulandele la manyathelo angezantsi ukulungisa ingxaki

1) Jonga umlomo ukuze uqinisekise ukuba umlomo uvaliwe

2) Coca intloko yoshicilelo. Ukuba ukucoca okuqhelekileyo akukwazi ukusombulula ingxaki, zama ukucoca nzulu

3) Khangela ukuba inani le-inki phantsi kweyunithi yokucoca liqhelekileyo (utywala buhla kwi-cap yeyunithi yokucoca ukujonga umphumo wokucoca) endaweni yokucoca iyunithi.

4) Faka esikhundleni intloko yoshicilelo

5) Buyisela imoto

6) Buyisela i-motherboard

【2】

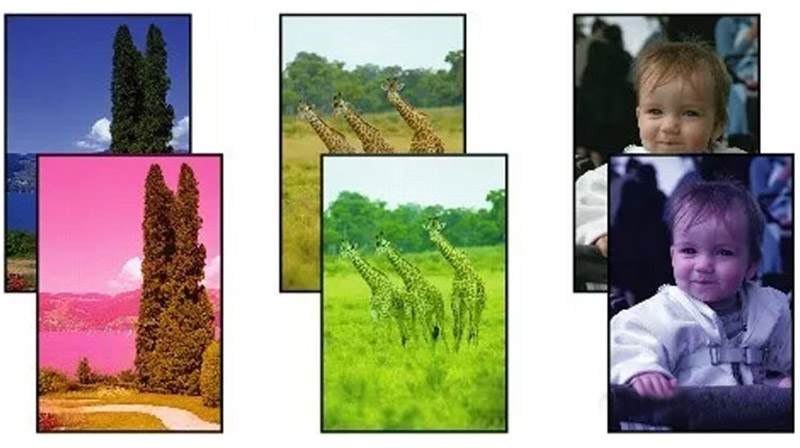

Umbala woshicilelo awukho, umbala wombala awukho

[Isizathu sokusilela] I-inki yombala othile ayizange ikhuphe kwintloko yoshicilelo kwaphela

[Ukusombulula ingxaki] Nceda ulandele la manyathelo angezantsi ukulungisa ingxaki

1) Khangela imeko ye-inki yekhatriji kwaye uqinisekise ukuba i-inki isetyenzisiwe.

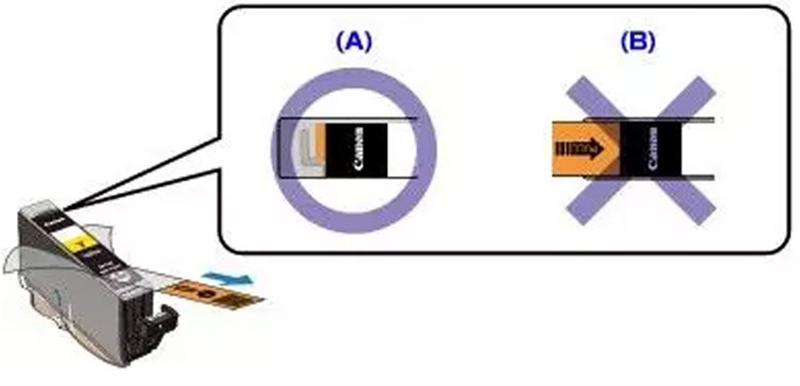

2) Khangela ukuba i-tape yokukhusela ye-cartridge isusiwe

3)Yenza ukujonga umlomo ukuqinisekisa ukuba intloko yoshicilelo ivaliwe.

(PS: bhekisa kwisisombululo esingentla sokushicilela imigca ethe tye kumanyathelo okuphelisa alandelayo)

【3】

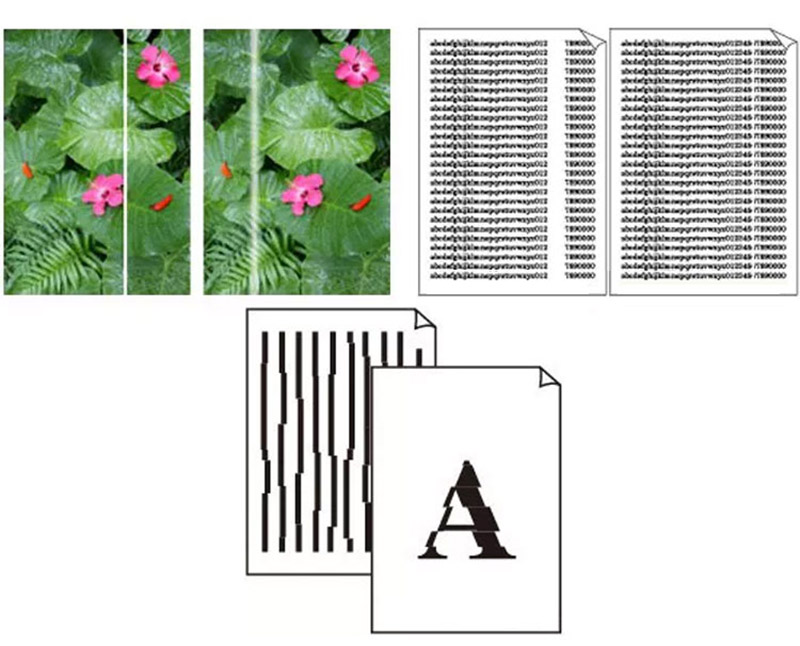

Indawo ezinzileyo yemigca emi nkqo, ukuprintwa kwe-dislocation

[I-Fault Analysis] Xa ushicilela, ukunyakaza okufanayo kwemoto ukuya kwindawo echaziweyo ilawulwa yi-coding sensor efunda i-grating bar.Ukuba kukho amabala okanye imikrwelo kwi-grating, iya kubangela ukuba ivili lokubhala lingahambi ngokulinganayo, okubangela imivimbo emi nkqo.

[Ukulungisa ingxaki]

1) Coca umtya wokugaya

2) Ukuba kukho imikrwelo kwi-grating strip, yitshintshe

3) igama lemoto yesilayidi igrisi ayifani, ioli yokuthambisa ngokulinganayo

【4】

Iifoto eziprintiweyo zimfiliba kwaye zineenkozo

[Isizathu sempazamo] i-inki eyehlayo ayinakutshiza ngokuchanekileyo kwindawo yokushicilela, ukuhla kwe-inki kukhulu kakhulu

[Ukulungisa ingxaki]

1) Qinisekisa ukuba ngaba ukhetho lwemidiya kwi-drive luchanekile

2) Misela umgangatho wokushicilela ukuba "phezulu" kumqhubi

3) Yenza ulungelelwaniso lwentloko yoshicilelo. Ukuba ulungelelwaniso oluzenzekelayo aluphumeleli, ulungelelwaniso lwezandla lungazanywa

4) lungisa ubude begama elithi imoto

5) Buyisela intloko yoshicilelo

【5】

Shicilela iifoto ezinemigca ethe tye (isithuba esiphakathi, esahlukileyo kwisithuba esincinci ngaphambili)

[Uhlalutyo lwempazamo] imigca enqamlezayo ephakathi, inokugqalwa njengenxulumene nesixhobo sokuhamba sephepha.

[Ukulungisa ingxaki]

1) Qinisekisa ukuba uhlobo lwemidiya oluchanekileyo lubekwe kumqhubi

2) Ingaba idiski ye-LF ye-grating ingcolile kwaye inothuli

3) Nokuba i-LF encoder imdaka okanye ayiqhelekanga

4) Ingaba ukunyanzeliswa kwebhanti akuqhelekanga, lungisa ukuxhatshazwa

5) Nokuba i-roller yokutya, i-roller yokucofa kunye ne-roller yokukhupha ayiqhelekanga, kwaye ukuba kunjalo, yitshintshe.

【6】

Shicilela iifoto, umphambili okanye umsila (malunga ne-3 cm) enemigca ethe tye okanye isenzeko soshicilelo esingalinganiyo.

[Uhlalutyo lwesiphoso] Ukuba iphepha lityiswa okanye likhutshwe kwizinga elingalinganiyo, i-inki encinci iya kutshizwa kwindawo yayo yangoku.Ibangela imivimbo okanye ukungalingani ngaphambili okanye ekupheleni kwephepha.

[Ukulungisa ingxaki]

1) Kukho into engalunganga ngeyunithi yevili le-spiking, buyisela iyunithi yevili le-spiking

2) Ukuba kukho ingxaki nge-feed roller okanye i-pressure roller, buyisela i-roller feed okanye i-pressure roller

Ixesha lokuposa: Jun-09-2021